Woodbe uses old technology to build with cross-laminated timber

Woodbe Engineering from Sweden uses an old proven technology in a new way in order to build smarter with cross-laminated timber. The innovation reduces the construction industry's climate footprint and improves the working environment for construction workers.

Cross-laminated timber is an example of a building material that is growing increasingly popular in the construction industry thanks to its environmental benefits, light weight and durability.

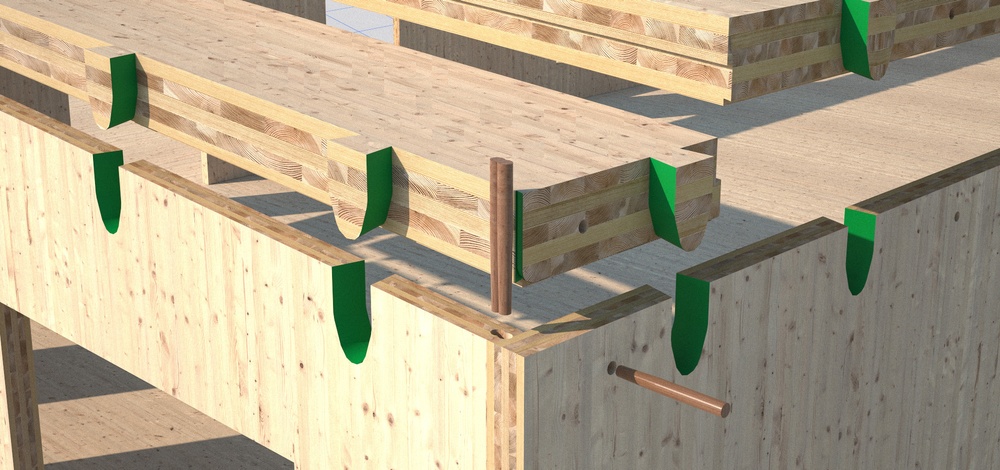

The startup company Woodbe has developed a self-locking frame system that creates completely new possibilities in cross-laminated timber constructions. The frame system has, among other things, been developed to reduce assembly time. The parts do not contain screws, angle irons or other metal connections but consist only of wood. Therefore, the frame system becomes circularly useful and is easy to assemble, disassemble and sort.

Without the need for additional connections, the system provides higher precision and reduces the risk of error at the construction site. Therefore, the technology saves time, money and contributes to a better working environment for construction workers.

Met at the university

Woodbe was founded by John Elwin Segolsson and Filip Palosaari. Between 2016 and 2019, they studied to become civil engineers, where they both focused on building construction technology. That is when the company idea was born.

“The construction workers work a lot with screws so we wanted to look at how to make the work more efficient. Then we started to ask ourselves – how did they do it in the past? How were old churches built? Well, they used finger joints and timber knots”, says John.

Easier for architects and civil engineers

Recently, they applied for patents and the response from large construction companies is positive. The next step is to create a reference case to enter the market. The long-term goal? To work full time with the company.

“Our product will make it easier for architects and civil engineers to build easily in wood. In the future, we want to see our technology in villas and smaller apartment buildings. We also want to get ideas to broaden the area of use of our product.”

Woodbe sees a bright future as they believe a lot is happening in the industry and there is a will and commitment to new innovations. Recently, they became a member of the internationally awarded bioeconomy cluster Paper Province in Sweden, which gives them a broad network in the forest industry.

“We believe that in the future it will be a matter of course to build in cross-laminated timber. But the wood industry must come up with better solutions and communicate the benefits better. Today, the knowledge about cross-laminated timber is inadequate. Therefore, people like to use concrete and steel, that they are already familiar with. But we want to be a part of that change!”

Contact

John Elwin Segolsson: john@woodbe.se

Filip Palosaari: filip@woodbe.se

Read more about Woodbe: www.woodbe.se

About Paper Province

Paper Province is a world-leading business cluster within the forest bio-economy. We are owned and operated by more than 100 member companies. The cluster is based in Karlstad, Sweden, and mainly operates in the province of Värmland and the surrounding area, but also nationally and globally. Together with our member companies we work towards sustainable development with focus on innovation, skilled work force, internationalization and regional mobilization.